The SR01 is the car we competed with in the UAE nationals on May 6th, 2012. We are extremely proud of this product and want to present it to you in full detail and answer any questions right here. Since we won the UAE Nationals we got to take part in the World Championships in October 2012, for which we of course designed and manufactured a new car we would like to present to you: The SR02.

The Main Innovation – Sapphire

…And this is where our team name originates from. We needed to make sure to have stable bearings, but we didn’t want any useless addition of weight, or friciton. And beleive us, we thought of tons of ideas! But none of them were satisfactory. Until we came to the idea of concentrating ourselves on watches, and precision measuring instruments, which led us to sapphire. And it worked: together with our steel axles, the sapphire generates almost no friction, and is the most important part of our car, already making it innovative.

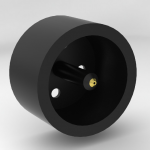

The Wheels

With the wheels, it was basically the same situation as with the bearings, with the main point being set on no useless addition of weight. We constructed our wheels to be closed on the outside, but open on the inside, to only use as much material as we really need. The wheels, which have small holes on the outside, are closed completely with stickers to prevent further unwanted airflow.

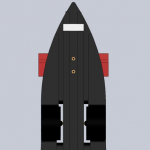

The Nosecone / Spoilers

One of the first features, we added to our car, was to ensure excellent aerodynamics by letting the air flow past the car on the sides, instead of guiding it over the car and creating downforce, which will not be the case with our car when we let it race. Together with front and back spoilers, as in real F1 cars, air flow is simply beautiful and has been tested in our self-built wind tunnel.

The Underbody

Even though the underbody doesn’t seem important in airflow, it could evolve to be a serious problem, especially if the underbody is so close to the ground surface, as with our car. Underpressure can be generated, which would rapidly deccelerate the speed of our car. So we had to solve this problem and built the most complex aerodynamic feature of our car. We milled two extra channels next to the teather line channel for air to pass through. Problem solved.

Tether Line Guides

We weren’t statisfied with the teather line guides that are provided by F1 in schools, which would just be bolted into the balsa would of the car. We looked at different alternatives and finally chose the so called PTFE tether line guide, a teflon bar, which is secured to the car by two carbon fiber rods.

Painting and Foiling

As always, we were still paying attention to the weight of the car while thinking about how to get some design on it. We found that we wouldn’t only have to paint the car, but we could also use foil, which would keep the car much lighter. So only part of the car was painted, and the remaining foiled, which at the end makes a beautiful contrast – The deep black from the paint, and the shiny red from the foil.

First test

Pictures say more than words … This time is amazing!

Overall, we are extremely excited about the product of long and hard work – The SR01. It’s innovations and absolutely georgeous design contribute to a sort of “wow”-effect. …This is revolution!

Check out all images of the SR01 here:

Nice job guys ! So how did you guys manage to have a spoiler behind the gas canister chamber? Was the part of the car behind the gas canister chamber a separate part or did you just drill the gas chamber deeper? Why did you guys choose sapphire bearings as ceramic ball bearings have a lower coefficient. Was it a weight problem? Also did the ridiculously thin axles give you any problems when it comes to stability. Any ways good luck in the world finals.

Thanks a lot! The whole car body is one part. The spoilers have been added at a space right behind the chamber and the back of the car. There is a small extra space before the actual gas chamber starts. Sapphire is our main innovation, which makes us who we are. With it, we don’t have to make us any big mind about friction. We wanted a material we can rely on, and that is being used for precise purposes, like watches. That’s how we came to sapphire. There was no weight problem at all. Every bit of the car has been calculated to not exceed our weight limit, including the painting of the car. And yes, the axles probably were a little too thin – They worked out fine, but it was tricky to keep them in a good condition, which we though managed until the race.

We are working on improving every bit of our car at the moment, as we have learned a lot through the UAE Nationals, and we’re already really excited of the result, which we most likely will call the SR02.

Hi Dan!

I’m Till the technical designer of Safire Racing!

First of all, thanks for you congratulations! To answer you questions:

The Body was milled from one piece, as it is not otherwise permitted and yes, we just drilled a deeper hole.

I think sapphire bearings have less friction than ball bearings but even if ball bearings would be faster, we would still use the sapphires because, as Chris said, they make us who we are and because they are our big innovation.

Yes, we had issues with the very thin axle, because we used a kind of steel which wasn’t stable enough, so the axle bended. For the world finals we will fix this issue by using a special and very strong type of steel.

All these improvements will be explained much further when we unveil the new SR02 in a few months!

Dear Safire Racing,

First of all, congrats on your win in the UAE nationals. Hope you guys outshine the other teams in the world finals.

You wrote that you used paint and foil for the car, which gave it a beautiful design AND kept the weight down. What is this foil and how does it work?

Thanks a lot for your help

Vishakh Kumar

Dear Mr. Kumar,

thanks for your congratulations!

We had some trouble, because the balsa wood is very blown and if you paint it completely with air brush, you would have to use a lot of paint, which would weigh a lot.

The foil, which is often used for real cars, is very strong and light. To adhere the foil, it is made hot and thus, it sticks to the surface. But the problem is, if you only use foil, the foil will also have the blowy surface of the balsa. That’s why we painted some areas with a primer, to make it smooth, before the foil was adhered. That gives us a very light, but strong and smooth surface painting.

Thanks to Glasurit and foil-a-car, we were able to get that idea working.

Kind regards

Till Blaha

Technical Designer

Hey Safire Racing!!

Your car looks great!!! How fast did it go? How long did it take to complete the track?

Hey, thanks a lot. During our tests it went at 1.099 seconds and during the race it went at around 1.13. We achieved 3rd on the fastest car table.